How to build:

A Hot Air Balloon Envelope

© 2007-2021 Keith Sproul

Web Pages worth looking at

Jump to Keith's Balloons

Jump to Pictures

Jump to Sewing Machines

Jump to Bottom

!!!! DISCLAIMER !!!!

Materials and ideas listed here are in part unproven and may be hazardous to use in the construction and operation of experimental hot air balloons. Building and flying experimental aircraft involves significant risk and may lead to serious injury or death. Always obtain professional advice when building or flying human-carrying aircraft!

This web site will explain how to build a modern hot air balloon. It will show a few different ways on how to do things, but it will not show all options. The intent of this is website to help somebody just starting by putting everything you need to know in one place. The information needed to make a balloon has been out there on the Internet, but the problem has been that it hasn't been easy to find. When you did find it, you couldn't find everything in one place, and you had to guess at some pieces of information. This website will have all the information needed to make a modern hot air balloon envelope. This is an ongoing project, and I welcome input, comments, and additions. The website is copyright by Keith Sproul. The information is public and may be distributed as anyone sees fit. If you redistribute this information, please provide links back to this website.

I -HIGHLY- recommend reading the balloon design directions at http://www.xlta.org/plans/index.html

There is lots of useful information there. The main difference between that website and this on is that the XLTA website has the design for a 54k / 16 gore envelope only. This site uses the Smalley Spread sheet and has the calculations so you can create any size envelope with any number of gores. You can use this to make a radio controlled balloon with a volume of less than 3,000 cu ft up to any size you want.

If you have comments, additions or corrections, please send them to me at ksproul@skychariot.com

Making a balloon is not as difficult as it sounds. Making a home-built airplane, even from a kit can take 3,000 hours.

With the modern quick-build kits, that can drop down to 1,000 to 1,500 hours or so, but you pay extra for the quick-build kit. Making an airplane from plans can take 5,000 hours.

Making a balloon can take anywhere from 150 to 300 hours. This is approximately 1/10 the amount of time it takes to make an airplane.

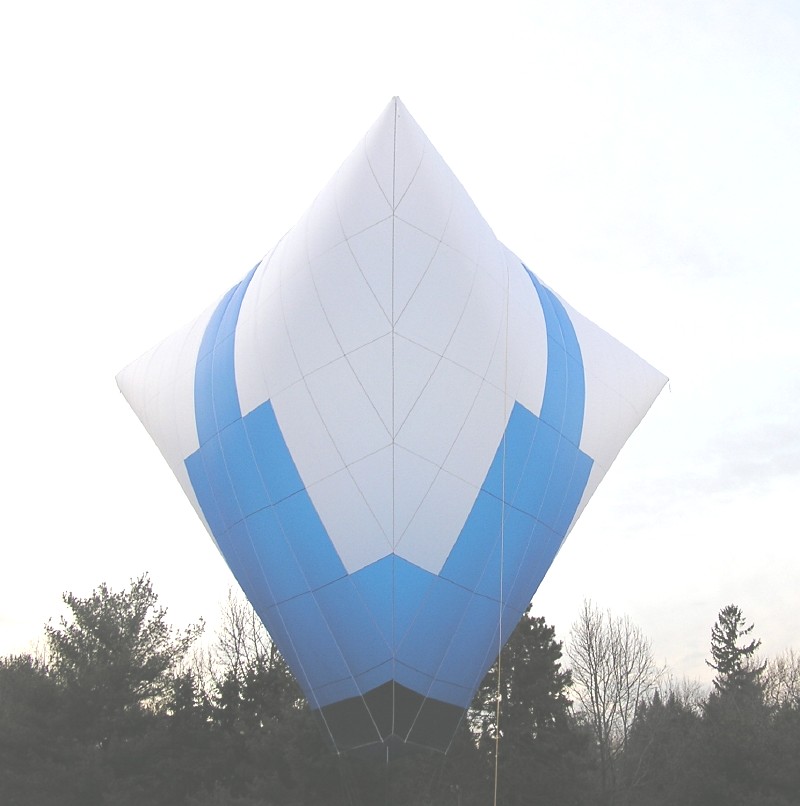

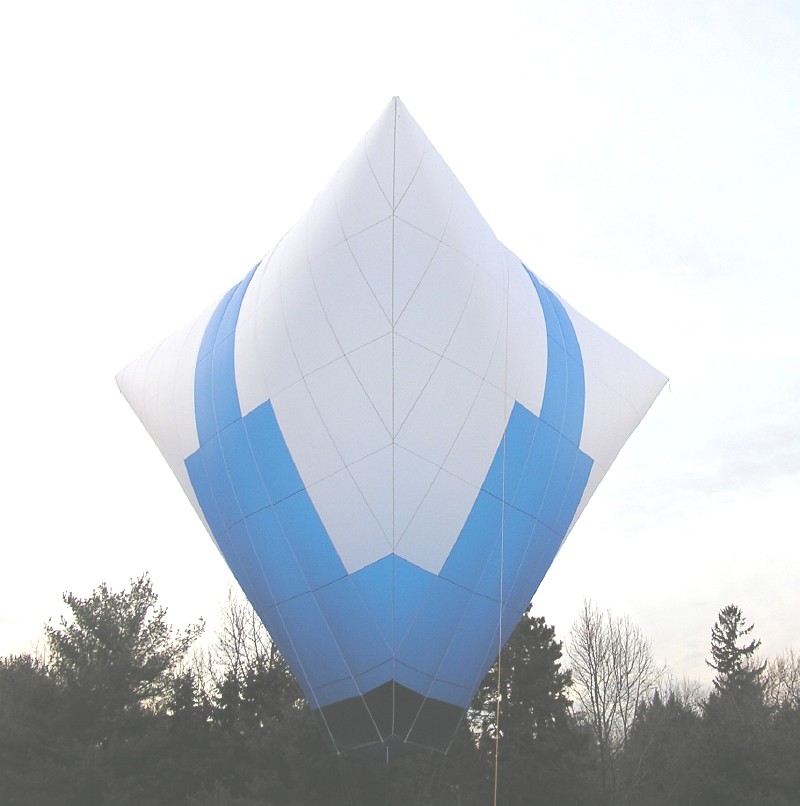

Sproul Construction Times

| Picture |

Registration |

Year Made |

Size |

Gores |

Time |

Comments |

|

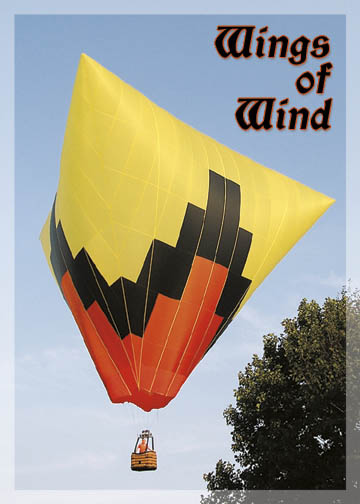

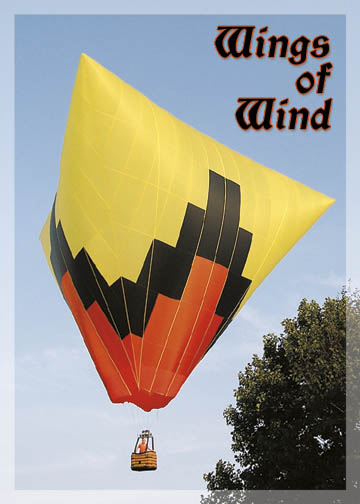

N-48KX |

2003 |

48,000 cu ft |

16 |

7 Weeks

175 hours |

First Balloon

Turning Vents |

|

N-73KX |

2004 |

73,000 cu ft |

24 |

5 months

250 hours |

Pattern took more time

Turning Vents |

|

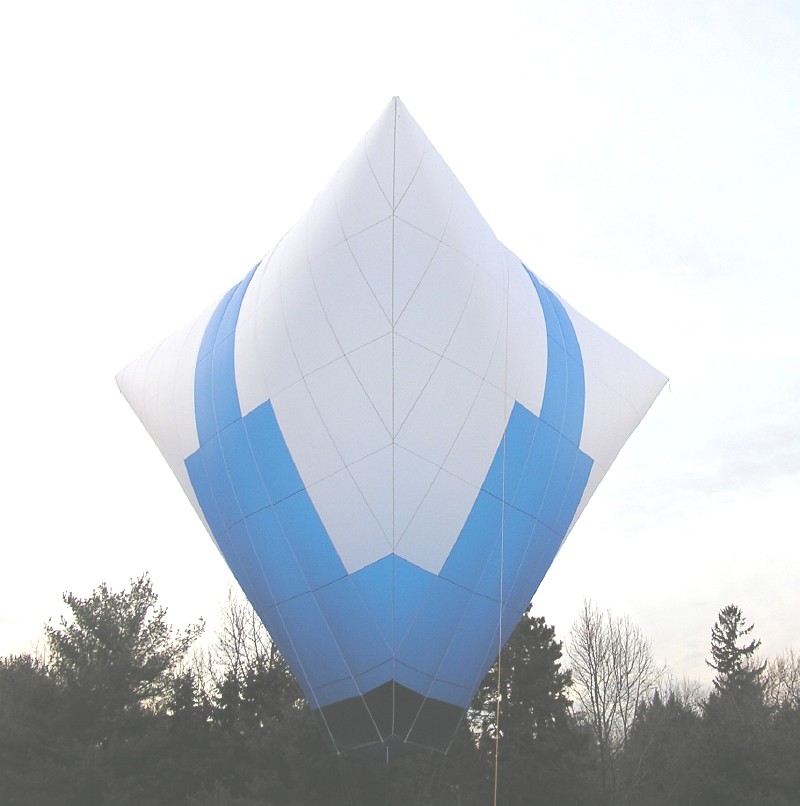

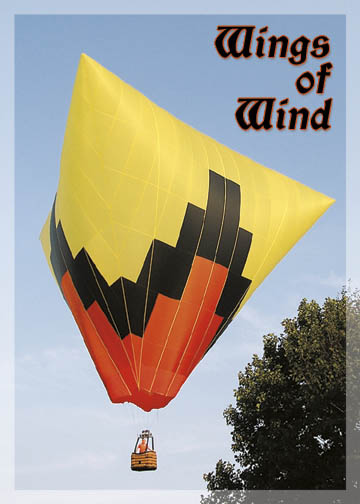

N-72KX |

2004 |

~90,000 cu ft |

3 sides

48 panels |

5 Months

150 hours |

Tetrahedron |

|

N-9713T |

2006 |

~60,000 cu ft |

3 sides

42 panels |

4 months

130 hours |

Tetrahedron |

|

N-72KX |

2010 |

~90,000 cu ft |

3 sides

48 panels |

16 months

210 hours |

Tetrahedron

Inlaid Stars were troublesome |

|

N-48KX |

2018 |

48,000 cu ft |

16 |

4 years

165 hours |

Rebuild of original LimeLight

Turning Vents |

|

N-83KX |

2019 |

83,000 cu ft |

16 |

4 months +

213 hours |

Larger version of Indecision

Turning Vents |

![]() |

N-83KX |

2024 |

83,000 cu ft |

16 |

Rebuild of Undecided |

Turning Vents |

![]() |

N-105KX |

2024 |

105,000+ cu ft |

24 |

-- |

Red/Blue Arror Balloon

Turning Vents |

|

N-49KX |

Future |

48,000 cu ft |

16 |

-- |

To fly with second T&C SkyChariot

Turning Vents |

Before you start, answer the following questions:

- Why do you want to make a balloon?

- What do you want to do with the balloon once it is done?

- How many people do you want to carry?

- What size of balloon do you want to make?

- How much time can you put into the project each week / month?

- Do you have space to dedicate to this project?

Or do you have to get it out and put it away each time you want to work on it?

|

Design Discussion

The information presented here will primarily discuss how to make horizontal-cut hot air balloon. This design we will use is what is known as the SMALLEY SPREAD SHEET. This is a spread sheet that will give you the dimensions you need to make a balloon. The Smalley spread sheet can be used for both vertical cut gores and horizontal cut gores. (You can also use the gore dimensions from the Areostar manual for the S49A, S50A, S51A, S52A, S53A, S55A, S57A, S60A, S71A, S77A and S81A envelope patterns.)

Making a horizontal cut gore balloon requires more cutting and more sewing. But, the cutting is MUCH easier, takes less space, and produces a stronger balloon. If you make a balloon with vertical cut gores, you need a hallway 10 feet wide and as long as your gores (80 - 100 feet). Since must of us don't have access to that, it is impractical to make balloons that way. In addition, by making a horizontal cut balloon, you get seams every five feet. These seams act as rip stops, and also as horizontal load tapes. With a vertical cut balloon, you have to add horizontal load tapes. With a horizontal cut balloon, you either don't need any horizontal load tapes at all, or maybe only one or two. In a horizontal cut balloon, All panels will be cut with straight edges, simplifying cutting and sewing.

| # of People | Size Cu Ft | Diameter Ft | Height Ft | Aprox Weight |

|---|

| 1 | 31,000 | 40 | 40 | < 100 lbs |

| 1-2 | 50,000 | 50 | 50 | |

| 2-3 | 77,000 | 55 | | |

| 3-4 | 90,000 | 57 | | |

| 4-5 | 105,000 | 60 | | 200 lbs |

| Pros & Cons of Experimental vs Commercial |

|---|

| Pros | Cons |

|---|

| Less Expensive than buying new | Can't fly Commercial |

| You can do your own inspections and repairs | |

| | |

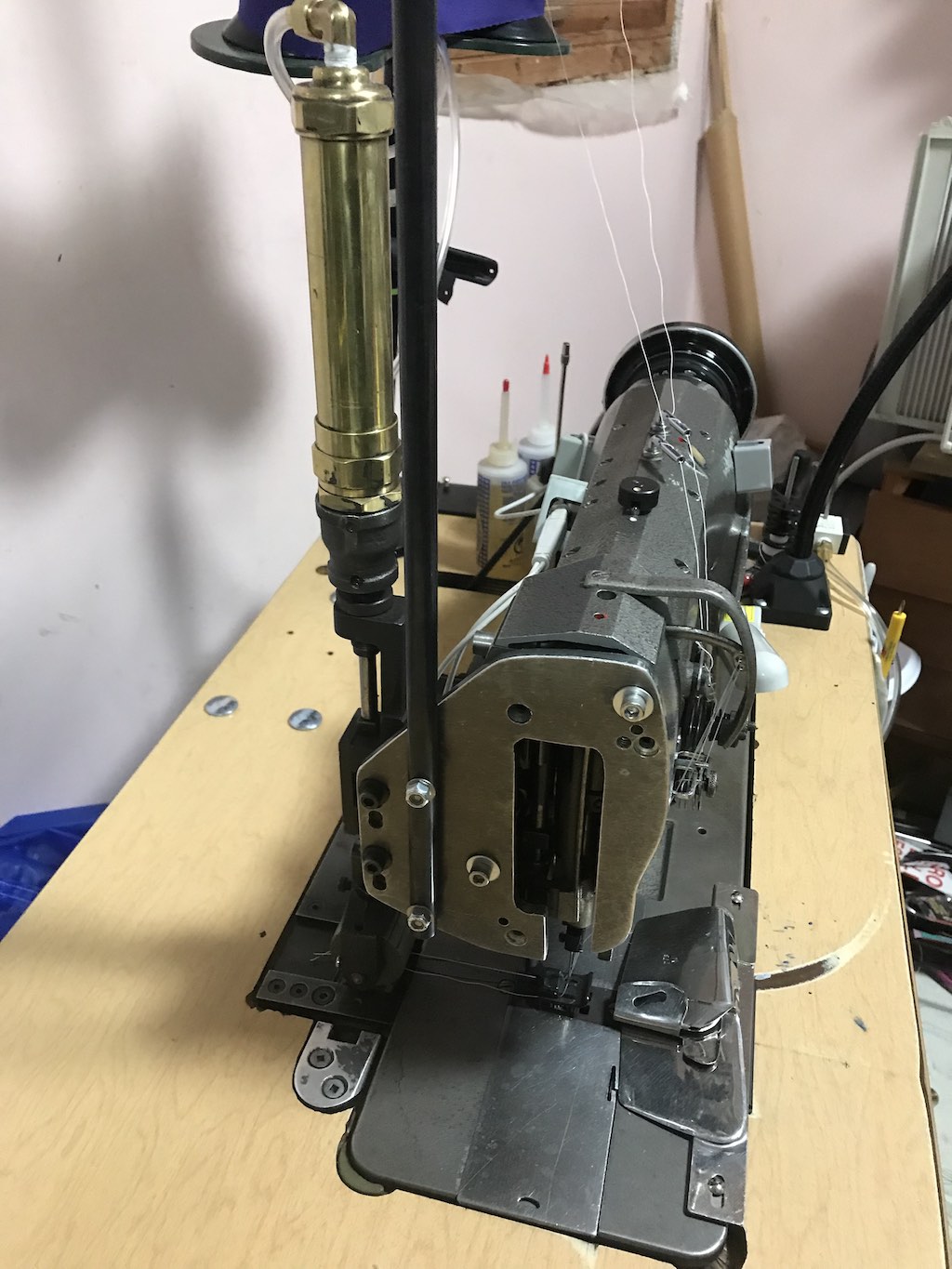

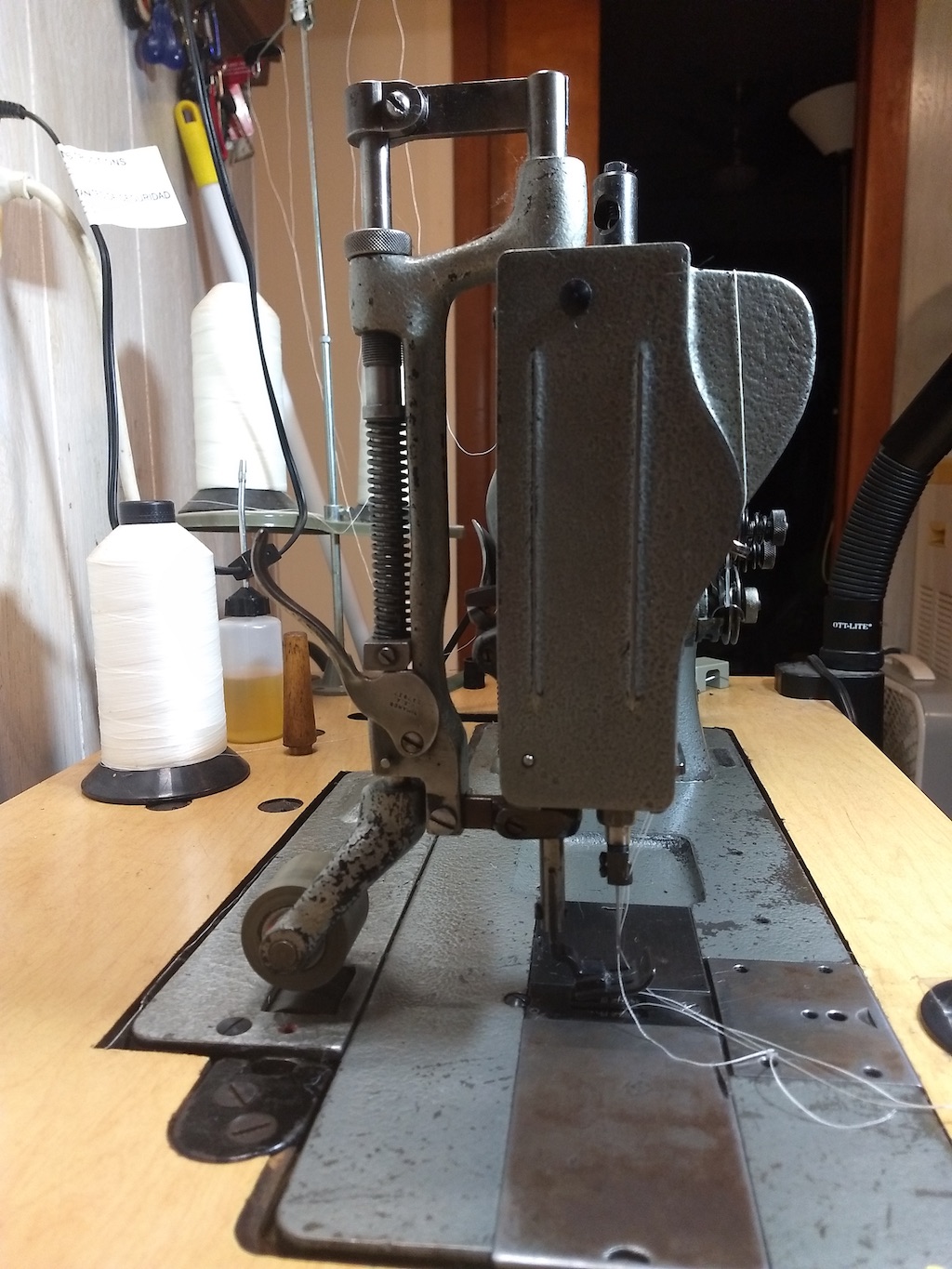

Sewing Machine Discussion

Having a good sewing machine can make all the difference in making a balloon. There are several good choices which can often be found on Ebay. My favorite is a sewing machine with a Puller. The Singer 112W116 has a puller, but this is an older machine. Even though it is an older model, it it is still a great choice. 212W120's can be found with pullers, but there isn't a specific model number for them that I have found. My favorite machines are the 212W120 with puller and a Consew 333RB with puller. The Consew 333RB has the advantage that has a much bigger bobbin, so you don't have to change bobbins as often.

You should be able to find a sewing machine between $300 and $900, maybe a little more with puller.

There are some options that you can do with the sewing machine after you get it.

- First Get a Servo Motor. This is a direct replacement for the clutch motor that has been standard for years. You can get a simple Servo Motor for about $100, or better yet, get one with needle position sensing for about $140. You can replace it your self in less than 1/2 hour. The advantages of a servo motor are:

- They don't run all the time, so they save on electricity

- They are very quiet compared to the standard clutch motor

- They have adjustable speed, VERY USEFUL

- Available with needle position sensor Also VERY USEFUL

|

The needle position sensor model allows you to have it always stop with the needle down, or always stop with the needle up. I prefer always stoping with the needle down. That makes it so the material doesn't move on you when you stop to reposition your hands.

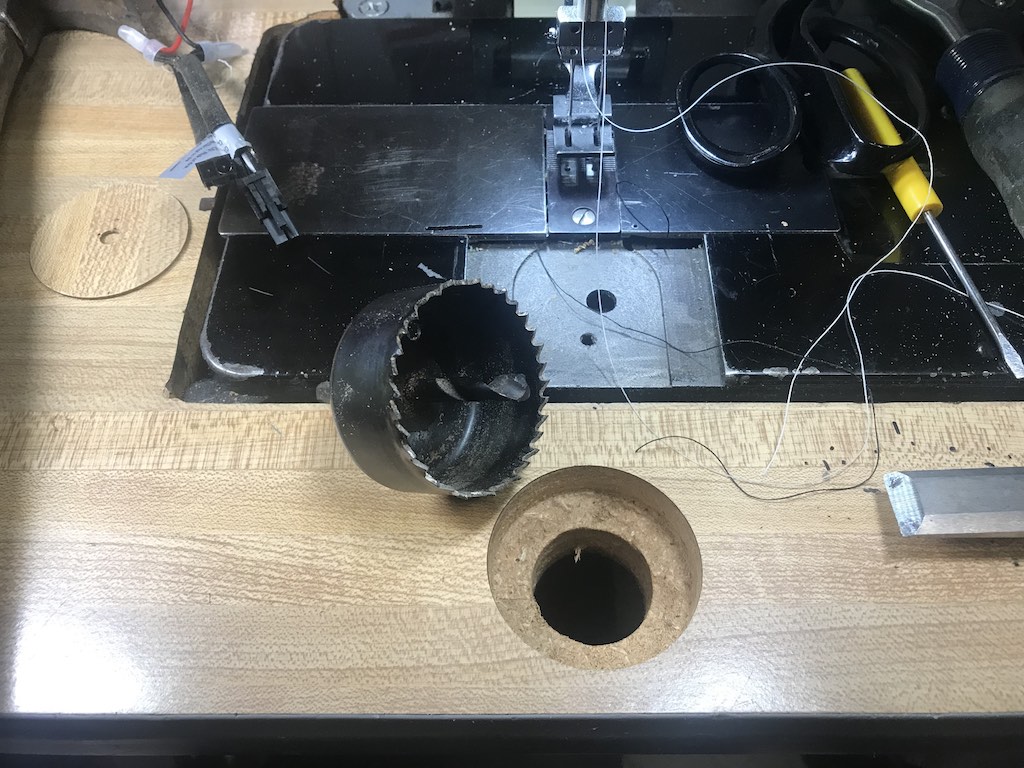

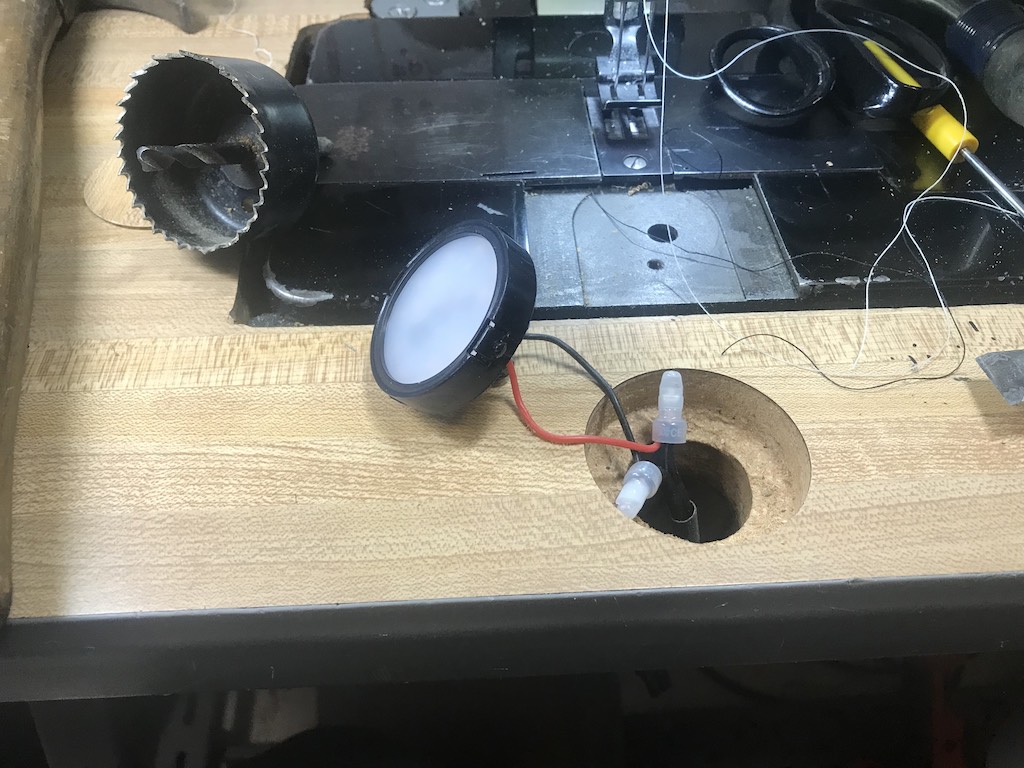

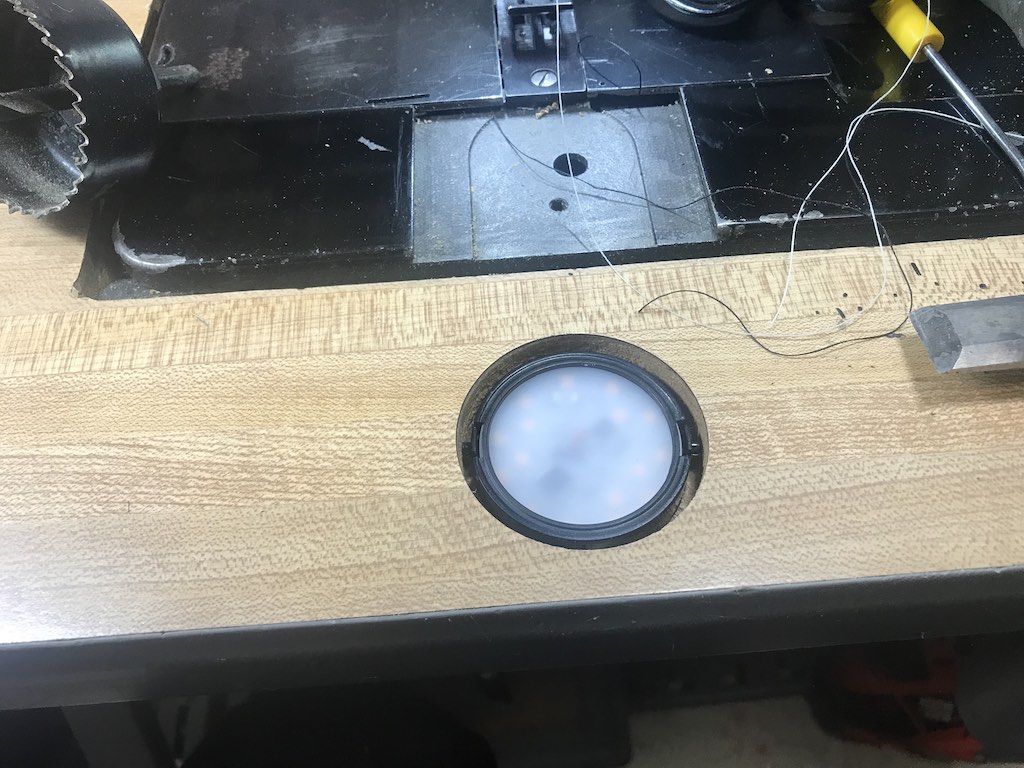

- Second You can install a light in front of the sewing foot. You do this by drilling a 2 inch recessed hole in the wood in front of the sewing foot. Install an LED light in the recessed hole and put clear packing tape over it. This light shows thru the fabric so that you can see if it is folded correctly.

|

See pictures of my Sewing Machines

Tools that you need |

|---|

| Cutting Table |

6' x 10' or longer ideal |

Pool table or Ping-Pong table will do

Put MDF (Medium Density Fiber board) on top for cutting surface. Also nice to have rotary cutting mats, but they are expensive |

Rotory Cutter

or good scissors |

|

Available at your local sewing store. |

| Double Needle Sewing Machine |

Consew 333RB

Singer 212w140

Singer 112w116

Singer 112w140

Brother

Juki

Pfaff |

3/8" needle spacing is preferred. You can change the spacing of a machine for less than $100

EBay is a good place to look

A puller is very nice, but not required. Pullers are also hard to find

Do NOT get a walking foot sewing machine |

| Seam Folder | | Tennessee Attachments

I highly recommend a seam folder. You need to get one designed specifically for your fabric and seam size. |

| Metal Rulers | 4 ft

6 ft

12 ft (or length of table) | Ace Hardware, Home Depot, Lowe's

12 ft is just a straight edge, and does not need to be a ruler

A pieces of 2" aluminum angle works well |

| Spring Clamps | | Ace Hardware, Home Depot, Lowe's |

| Marking Pencils | Sharpies

White Fabric Pencils | Various colors of Sharpe's Especially Silver for dark fabrics |

| Masking Tape | 2" wide Normal Masking Tape | Ace Hardware, Home Depot, Lowe's

Buy the Contractors pack (10 rolls in a package). Don't get the Blue stuff, also don't get the tape marked as "LOW TACK". |

Materials that you need |

| Material | Quantity | Source / Comments |

| Nylon | 500 - 1000 yards |

MagnaFabrics.com

www.westmarkcorp.com

|

| Load Tape | 500 - 1000 yards |

www.ballyribbon.com

kwwebbing.com

www.pamnarrowfabrics.com

tnwebbing.com

|

| Nomex | 20 - 40 yards | Tex Sales, Montreal, Canada (Was Difco Performance Products)

www.davisinteriors.com |

| Crown Ring | 1 (4" - 11" Metal Ring) | From an old balloon |

| V-Rings | 1 per gore | From an old balloon or

Forgecraft (Part # 54A90B2)

www.dj-associates.com |

Quick-Links /

Rapide Links | 1 per gore | www.dj-associates.com |

Hook & Loop Fastners

(Velcro) | 2" wide for Parachute

6" - 8" per gore | Get the sew-on kind, NOT the stick-on kind |

| Pulley(s) | 1 or 2 for Parachute

1 for each turning vent | From an old balloon |

Caribiners

or A-Blocks | 4 | From an old Balloon

http://www.stumpfballoons.com/carabine.htm

Many other sources |

1/8" or 3/32" Aircraft Cable

7/19 Galvanized | 10-15' per gore |

Aircraft Spruce and many other sources

|

| Cable Thimbles | 1 per gore |

Aircraft Spruce and many other sources |

| Nicopress Fittings | 1 1/2 per gore |

Aircraft Spruce and many other sources |

Red Line

Vent Lines | | From an old balloon or

-GOOD- polyester braided rope NON-stretchy |

| Thread | Polyester Bonded

Size 69 or Size 92

Left Twist

3 1 lb cones/spools |

Do not use Nylon. Polyester is much better. Make sure it is bonded. You will need three cones of thread, one for each needle and one for the bobbins.

I prefer getting the pre-wound bobbins, but that costs a little more

www.thethreadexchange.com

|

Steps to make a Horizontal Cut Smalley Design Hot Air Balloon Envelope

- Start a Construction Log Book

I use a FileMaker database. You can use a paper bound note book, Excel, Microsoft Access, or what ever you are comfortable with. The FAA requires the 51% rule for Amateur Built aircraft. Having a log book to show everything you have done is excellent proof that you did indeed do the construction yourself. It is a good idea to take pictures as you go too. Keeping a log book makes it easy to keep track of how much money and time you spend on the project. An electronic log book makes this even easier.

- Practice

If you are new to sewing, practice sewing the French Felled Seam or Folded Fell Seam. Practice a LOT. Make sure that your sewing machine is adjusted to your fabric and thread. See http://www.apexballoons.com/tips/ for tips and instructions on how to do a proper seam.

- Determine Size of Balloon

Decide what size balloon you want to make. Also decide on number of gores. See Discussion on Balloon Size.

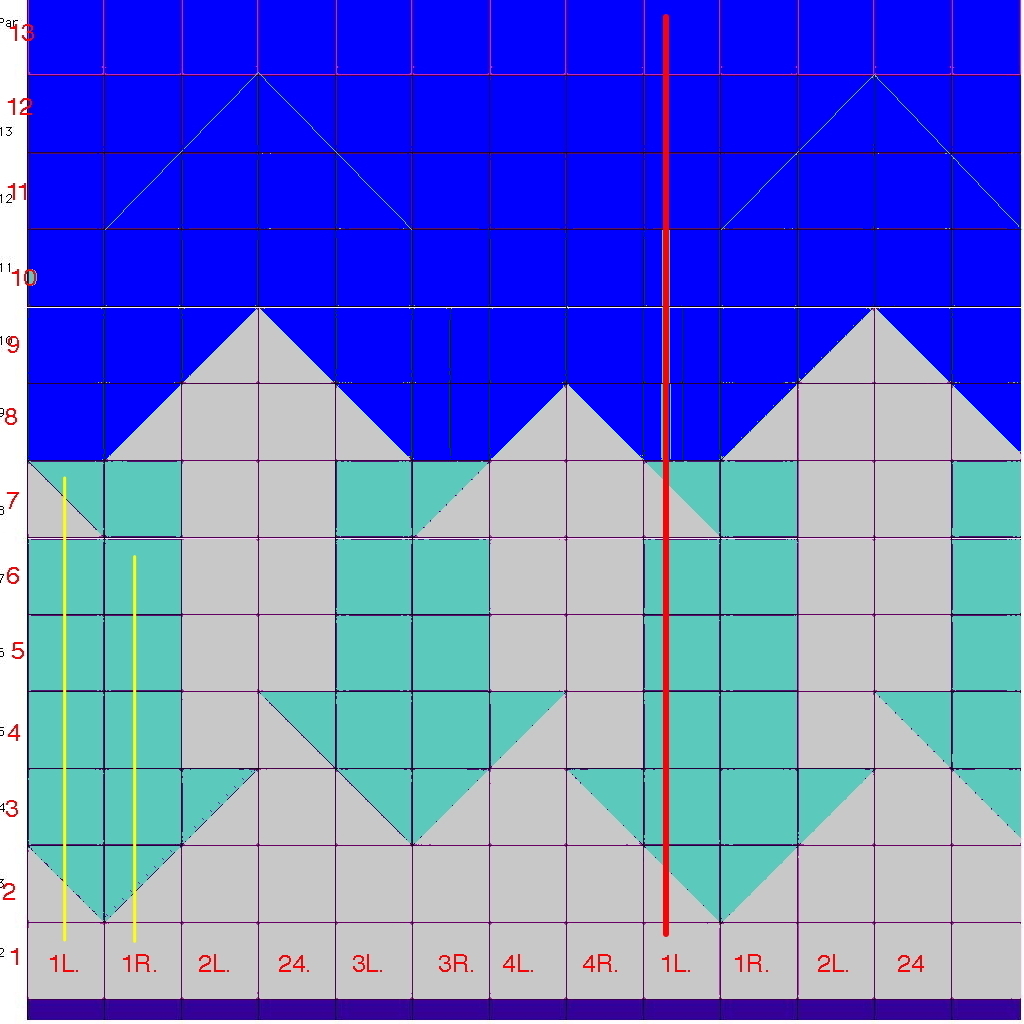

- Make the design, colors, etc

Do not get too complex (At least not on your first one) Use a paint program and play with colors. Inlaid designs are very difficult for the beginner. See discussion on Balloon Color.

- Calculate Panel Dimensions

See Discussion on Calculating Panel Dimensions. Figure out how many panels of each color you need. Order at least 15% more than you need, and if are buying seconds, buy 25% more.

- Buy Materials

Most places only sell by the roll. They often have different size rolls in stock. Ask what they have in stock and buy what fits your needs.

- Apply for N-Number

http://registry.faa.gov/aircraftinquiry/aircraft_inquiry.aspx

http://aircraft.faa.gov/e.gov/NN/reserve.aspx

It is easier to apply for a special N-number than it is to get one 'assigned'

- Registration

Send in Registration Application and Amateur Built Affidavit. Yes, do this early.

Registration ApplicationAC8050-1.pdf

Amateur Built Ownership Affidvait

- Cut Panels

Advisable to cut all panels before starting to sew. See discussion on Cutting Fabric.

Consider cutting one or two extra panels for later repairs. This is more practical for balloons with only one or two colors. If you do decide to do this, make sure you order a little extra fabric.

- Sew Panels into Vertical Half Gores

Easy sewing, LOTS of short seams.

Make the seam so that it sheds water. This is so that when the balloon is upright, the lip faces down. Think of it this way, you don't want a ridge that collects dust. With the way most people sew the folded-feld seam, this means start at the bottom of the gore and work your way up.

- Sew Vertical Half Gores into Full Gores

Lots of LONG seams. This is the CURVED seam.

Make sure you start with FRESH FULL Bobbins each time. Unless you are making a really big balloon, a full bobbin should be enough to finish the entire seam. Changing bobbins mid-seam is a pain. It is doable, but avoid it if you can.

- Install Turning Vents

If you are going to make turning vents, do it here. Take 3 full vertical gores and sew them together. Then make the turning vents in this set of 3 gores. Then use this set of 3 gores as the beginning of the next step. See http://www.skychariot.com/vent.html for more detailed directions on how to make turning vents.

- Sew Full Gores together

Start at one side. Sew each gore onto the previous gore. If you have a pattern, make sure you get the gores in the correct order. The vertical load tape gets attached here. Using a Tape Foot is highly recommended but not required. Some people prefer to not use a tape foot. See picture of a tape foot below.

You need to put two layers of load tape for the bottom 18" to 24". You also need to have the same amount extra to sew back on the inside. This gives you two layers of load tape going thru the V-Ring, with 18" to 24" going back up inside.

- Sew in Temperature Wire Sleeve

Determine which gore you want the sleeve for the temperature wire. It is usually on one of the bottom-left gores, as you are looking up into the balloon when it is being cold inflated. When you get that seam finished, turn the balloon over and sew the sleeve onto the inside of the load tape. Don't forget this. Adding it later is VERY difficult. Instead of a sleeve, you can sew in tie straps. At every other horizontal seam, sew in a 12" piece of 3/4" or 1" piece of load tape. If you are going to use a wireless temperature sensor, you do not need to do this. But I recommend putting in the tie straps at minimum incase you ever change your mind.

To make the sleeve, take scraps (the longer the better) cut it 8" - 10" wide and sew them into a tube. You want to end up with a tube 4-6" wide. You want to have breaks in the sleeve at every 20" or less to make it easier to feed the wire.

- Sew Horizontal Load Tapes

If you are going to have any horizontal load tapes, attach them now, before the last seam is sewn. Horizontal load tapes are best sewn on top of a seam. Leave 18" overlap so that when the last seam is sewn you can come back and overlap the load tape on top of itself.

- Sew in Parachute Centering Line Attachments

With the envelope still open, go in and sew in attachment points at the second or third seam down from the parachute opening. These are best attached to the load tape at a seam intersection. This can be done after the envelope is closed up, but it is a little easier to do it before.

- Sew the Last Seam

This is actually a little easier than it sounds. Double check EVERYTHING before you start this step. There are many things that need to be done before you close up the envelope, many of them are MUCH MUCH easier with the balloon still able to be laid out flat.

Lay the balloon around the sewing machine, with the left edge to the left of the machine and the right edge of the balloon behind the machine.

- Finish any Horizontal Load Tapes

If you have any Horizontal load tapes, go back up the last seam and overlap them so they are continuous around the balloon.

- Attach V-Rings

Take the load tape, put a V-Ring on it, overlap it at least 18 inches inside the balloon.

Then sew a second layer of load tape 18 - 24 inches overlapped on the inside and outside of the balloon. Sew back and forth over all of this at least 4 passes. Note: You are going through four layers of load tape and 4 layers of Nomex.

If you want to be neat about this, put the second layer of load tape UNDER the first layer, thus hiding the ends of the second piece of load tape. If you are going to do this, you have to know it before you begin sewing vertical load tapes because you have to leave the bottom 18 inches of the seam unsewn (Or you have to rip out the seam).

- Sew Bottom Girdle

Use either 1" Load Tape, 1 1/2" Load Tape or 2" Seat Belt Webbing to make the girdle. I like using seat belt webbing, but 1" load tape is sufficient. That is what Aerostar uses.

- Optional: Load Tape Protectors

I suggest putting a layer of Nomex over the load tape on the inside of the balloon. This protects the thread on the load tape. Make 6" wide strips of Nomex. Sew them on top of the load tape, with 1" folded under on each side, making a 4" wide strip over the top of the load tape. The dimensions given are just suggestions.

sSew Parachute Girdle

Use 1" Load Tape to make the girdle.

- Sew in Crown Ring

- Calculate the Diameter of the Parachute Opening

Measure the EXACT Circumference of parachute opening. This can be done by measuring the width of each gore, until you are sure they are approximately the same, and then multiple by the number of gores. Divide the circumference by PI (3.14159265) to get the DIAMETER. Divide this by 2 to get the RADIUS.

- Measure the crown ring

Measure the INSIDE diameter of your crown ring. Divide by 2 to get the radius.

- Calculate the length of the load tape

Subtract the radius of the inside of the crown ring from the radius of the parachute opening.

- Mark each load tape

Go to each load tape. Measure up from the parachute girdle to the dimension calculated above.

Mark there. Then mark another 24" up from that.

Cut the load tape at this second mark.

- Attach load tape to crown ring

Fold the load tape over the crown ring at the first mark. To make it look nice, fold the load tape from the outside to the inside. That way the end of the load tape will be hidden inside.

Use a safety pin to hold the load tape together

Do this for all load tapes

Spread the entire thing out to visually check to make sure it is correct.

Once you have double checked everything, go back and sew the load tapes. Do at least 4 passes on the load tape.

- Sew in Spider Web

If the balloon is larger than 77k, you should put in a spider web. Measure in about 1/3 from the outside of the parachute opening. Measure the distance to the exact center of the crown ring. This is the Radius at that point. Multiple by 2 * pi (3.14159265). This is the circumference at that point. Divide this by the number of gores. This give you the dimension between load tapes at that point Distance-D. Take a piece of load tape that is longer than this circumference. Mark it every Distance-D. Sew this circumferential band on the load tapes at the points marked above

- Make Parachute

ccCalculate Parachute Diameter

Using the parachute opening diameter determined above, calculate the diameter of the parachute. Make sure you have at least 12 - 18 inch overlap, on bigger balloons you might even consider going to 20 inches. NOTE: This is added onto the RADIUS, so the diameter is 24-36 inches larger than the opening.

- Parachute Design

The parachute can either be made by making pie-shaped gores, or simple horizontal panels making circle the diameter needed. If you are using the Smalley spread sheet, it will give you the dimensions needed all the way to the center.

- Parachute Artwork

Consider putting some sort of artwork on the parachute, at minimum a smiley face is nice.

See http://www.skychariot.com/BalloonParachutes.html

- Centering Line Attachment Points

Attach the centering line attachment points to the parachute. Use 18 - 24 inch pieces of load tape, with the parachute sandwiched in between the load tape.

- Outer Load Tape

Sew a row of load tape all the way around the parachute. Put the load tape on the INSIDE of the parachute. This gives the parachute a smoother surface to seal against the inside of the balloon.

- Parachute Velcro on Parachute

Sew Velcro on top of each attachment point. Use 2" Velcro, 6" long.

- Parachute Velcro on Balloon

Install Velcro Parachute Holding tabs in balloon

Can't be done until parachute is finished to make sure they are in correct location

- Install Parachute Rigging

Install the Parachute by tying in the Centering lines. Attach the shroud lines then attach the Red Line and its pulleys

The parachute centering lines may take some adjusting.

- Make and Install Basket Cables

Use NICOPRESS fittings. Make sure you use the Go/No-Go gauge to test EVERY fitting, Alternatively, you can use cables from a dead balloon. IF the old balloon has the same number of gores and approximately the same mouth diameter. Using the cables from an old balloon, or using the cable dimensions from a known balloon design makes this a lot easier. See discussion on Basket Cables

- Make Skirt or Scoop

If you made the number of gores and width of the bottom of the balloon the same as an existing balloon design, you can use patterns from that same balloon. I like making the skirt or scoop out of Nomex. This is more expensive, but I feel it is worth it. I prefer a scoop. It takes less material, and helps on windy inflations and tethers.

- Test Inflation

Take it slow. Check everything, especially parachute centering lines.

Take lots of pictures!

- Write Manual

FAA requires a flight manual. Look at other balloon manuals. Keep it simple. Don't put in any undo restrictions. Make your options flexible. Remember: If it is in the manual, it is probably okay.

- FAA Paperwork

Fun! 8130-6, 8130-12

- FAA Inspection

DAR (Designated Airworthiness Representative) or FAA direct. Using a DAR is easier, but costs money (typical is $300 - $400). The FAA is free, but they aren't as flexible in time.

- Test Flights

FAA requires 10 hours of testing in a 25 mile radius of a given airport. They usually require at least the first flight to be solo. Sometimes they may require all 10 hours to be solo. This will vary by FISDO. If flying a balloon solo that is designed for more than one person, make sure you take extra ballast with you.

Take lots of pictures!!

|

Discussion of Steps

sBalloon Size

Balloon Size depends on a lot of things. How many people do you want to fly? How big you are? What type of temperatures do you fly in? If the balloon is too small, you will easily overheat it. If it is too big, it can be hard to bring down. Yes, this sounds hard to belive, but it is true. Also, if the balloon is too big, you will be under-pressurized. This will allow the balloon to cave in on the sides if you go thru bad wind-shears. I like to fly balloons cool, so I usually make them a little bigger than needed, but you don't want them too big.

You also need to decide on the number of gores. For smaller balloons, 16 gores is usually enough. If you are making a balloon larger than 77k, you should consider 24 gores. The more gores, the smoother / rounder the balloon. Less gores make the balloon more bulbous.

- Balloon Color / Pattern

KISS Keep It Simple Stupid. Especially on your first balloon. Having different panels different colors is very easy. Inlaid designs are difficult and not recommended for the beginner.

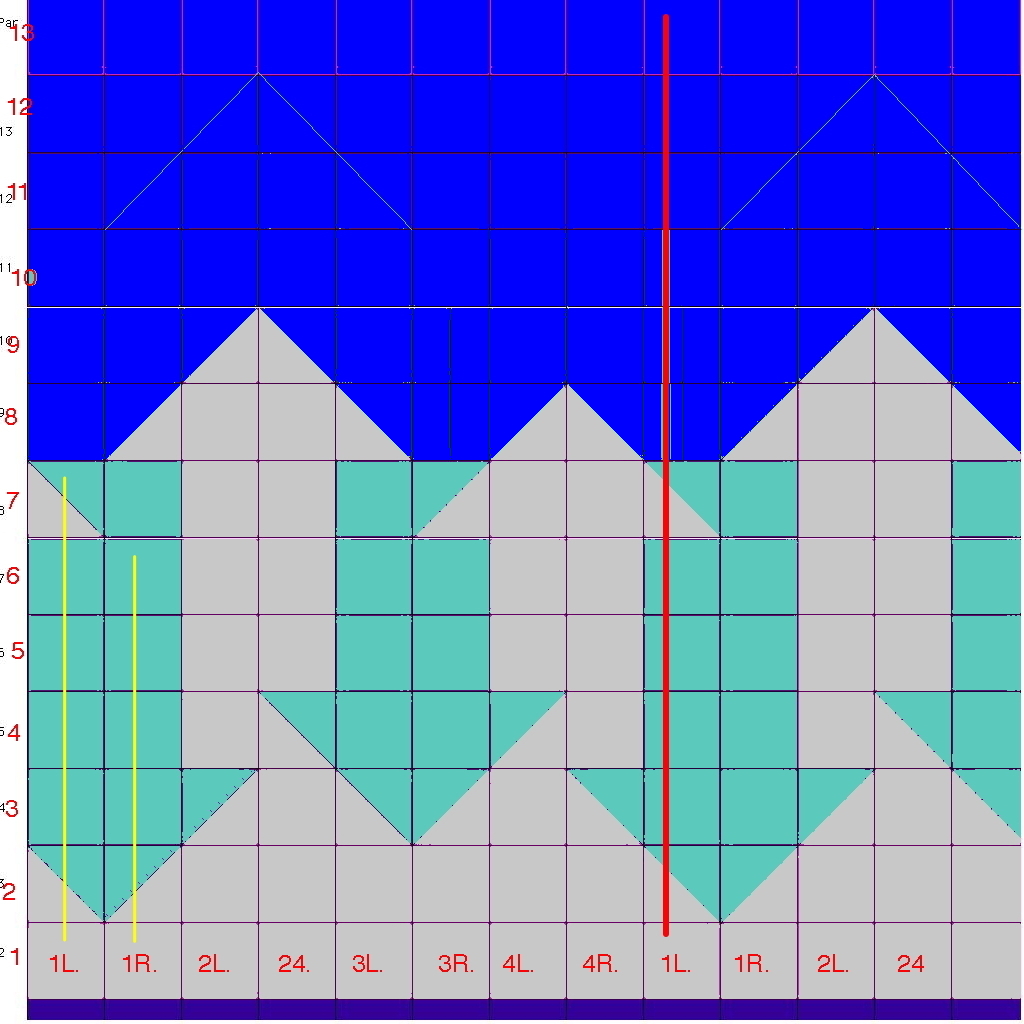

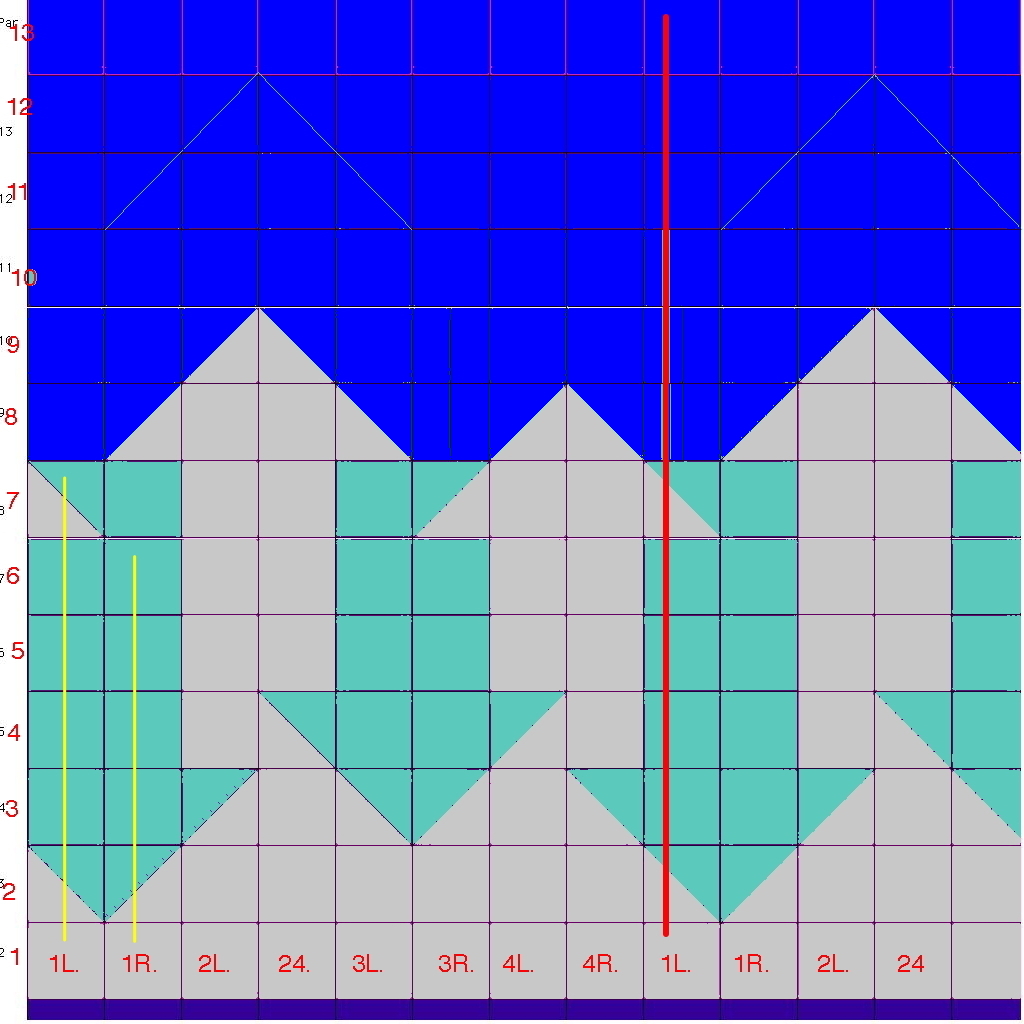

- Calculating Panel Dimensions

Calculating the actual dimensions of the panels can be one of the hardest steps in this project. The Smalley Spread Sheet itself only gives the dimensions for a vertical cut balloon. If you are not comfortable with simple algebra, this step can be very daunting.

- Determine the width of your fabric.

Nomex is normally 60" wide. The 1.3 oz Silicone that many of us uses is normally 65" wide. Other types of Nylon are often 60". If you are lucky, all of your rolls of fabric are the exact same width. If not, you will have to cut the fabric to the same width (except for the Nomex, we will treat that separately). You can have different panel heights in your balloon, but this gets confusing and is not recomended. Any panel will have to be the height of the width of the narrowest color in that panel.

- Determine the width of the bottom panel

This should be made the same as a known balloon design so you can use cables, skirts, and scoops from that balloon design. For example, for the Aerostar S55A (77K), S57A (90K), and S60A (105K) This bottom dimension is 11.70 inches and for the Aurora S53A (69K) and S49A (54K) the dimension is 16.25 inches. The Smalley Spread sheet, or the Aerostar panel dimensions give you fabric widths at different station points along the gore length, but never in the exact place that you need the dimension. So you have to interpolate between the given widths to get the needed widths. This can be done using on-line interpolation tools.

For example http://www.ajdesigner.com/phpinterpolation/linear_interpolation_equation.php. The version of the Smallley Spread Sheet that I give out has this interpolation calculation in the spread sheet. You still have to type in the numbers to get the dimensions you need for your balloon size. If you are having problems with this, let me know and I will be happy to do a set of dimensions for you.

- Calculate the dimensions of the rest of the panels

Using the width of your fabric, go up the gore and find your next cut point. Use the interpolation, calculate the width at that point. Then go back down 2.25 inches (this is TWICE the overlap dimension of 1.125 inches) and interpolate again. The interpolation calculations in my spread sheet do both of these at the same time. This saves on typing.

- Cutting Table

The biggest space you will need is a cutting table. If you have a Pool Table or a Ping Pong Table you have all the space you need.

Ideally, a table 6' by 12' (or longer) works great for cutting. Use MDF (Medium Density Fiberboard) and make a table top to go on top of your pool table or ping-pong table. Make sure your table top is perfectly square, you will be using it as your measurement references for all cutting.

- Cutting Fabric

Most types of Nylon have a 'top side' and a 'bottom side' to the fabric. Most fabrics also have a slight difference in color depending on which side is out. So, you need to cut half of the panels so that you get left side and half so you have a right side. You can do this by cutting half 'face up' and half 'face down'. Also, it is HIGHLY advisable to mark each and every panel with what panel # it is and note somehow that what side of the fabric is 'top'. If you write small at the edge of the fabric, it will be sewn into a seam and never seen. I recommend picking a place on the panel, and writing in the same place on every panel. For example, I write on the straight edge on the bottom of the panel. For example, in the drawing below, I write where the '+' is. By writing in the same place on every panel, you don't have to go searching for the label, you know exactly where it is. For dark colors, use Silver Sharpe's. Write small, less then 3/4" on the edge of the panel.

The easiest way to cut fabric is to use a rotary cutter (looks like a pizza cutter). But the that requires getting cutting mats to put on top of the cutting table. This is expensive. Another good choice is the electric rotary cutters. They do not require cutting mats. They can easily go thru 24 layers of fabric.

The spread sheet gives you top and bottom dimensions for each panel. Lets call those W-Top and W-Bot.

W-Top W-Bot

|-------------/-------+

|------------/--------|

|-----------/---------|

|----------/----------|

|---------/-----------|

|--------/------------|

+-------/-------------|

W-Bot W-Top

I lay down a layer of fabric, tape it down with 2" Masking Tape and then add another layer, and another, and another. Typically, I cut between 8 and 12 layers at a time. 12 is about maximum. The other limit is how many layers you can get taped down and keep them straight. The silicone nylon is slippery and since the tape does not stick well, it is hard to keep taped down well.

By cutting this way, you get two panels per layer of fabric. It speeds up cutting and reduces waste.

If you have a longer cutting table, you can even save more time by cutting more than one panel/pair at a time. This saves on time because it takes about the same amount of time to lay out the fabric, no matter what the length, and it saves on waste because you have the same amount of waste per layer if you are cutting one panel/pair or two panel/pairs.

W-Top1 W-Bot1 W-Top2 W-Bot2

|-------------/-------|-------------/-------|

|------------/--------|------------/--------|

|-----------/---------|-----------/---------|

|----------/----------|----------/----------|

|---------/-----------|---------/-----------|

|--------/------------|--------/------------|

|-------/-------------|-------/-------------|

W-Bot1 W-Top1 W-Bot2 W-Top2

W-Top1 W-Bot1 W-Top2 W-Bot2 W-Top3 W-Bot3

|-------------/-------|-------------/-------|-------------/-------|

|------------/--------|------------/--------|------------/--------|

|-----------/---------|-----------/---------|-----------/---------|

|----------/----------|----------/----------|----------/----------|

|---------/-----------|---------/-----------|---------/-----------|

|--------/------------|--------/------------|--------/------------|

|-------/-------------|-------/-------------|-------/-------------|

W-Bot1 W-Top1 W-Bot2 W-Top2 W-Bot3 W-Top3

- Thread

Aerostar and others use Polyester #69 Bonded Thread. Cameron uses Nylon. I prefer Polyester for two reasons. It doesn't stretch as much, and it has a higher melting point than Nylon.

White is used most often, but depending on the color of your fabric and the needs for the design, you can use colored thread. If you use a thread the same color as your fabric it is much harder to see when you need to rip out a seam. I like to have white thread on the top and black thread on the bottom (bobbins). The contrasting colors makes it real easy to see how well your stitches are being made. For a good description on how the stitching is supposed to be, see Jon Radowski's Web Page How to Sew a Balloon

I like to buy pre-wound bobbins. It is much easier, but it is a little more expensive than winding your own. I buy my thread from www.thethreadexchange.com

- Basket Cables

If you use the mouth dimension of an existing balloon, you can use the cable dimensions from that balloon, or better yet, get cables from a dead balloon. If you are making a 16 gore balloon, use the dimensions from an Aerostar Aurora, S49A / S-53A which are both 16 gore balloons with the same bottom dimensions.

If you are making a 24 gore balloon use the dimensions of the Aeristar S-55A / S-57A / S60A which are all 24 gores balloons with the same bottom dimensions. Cameron / Lindstrand or other brand dimensions and cables will work just as well.

To make this work, the dimension of the bottom of the gore has to match the balloon you are copying the cables from.

See discussion about Calculating Panel Dimensions.

|

|